This post is a follow-up and is best read after reading How Many Distribution Centers Do I Need For One-Day Delivery?

In our previous post, we showed how supply chain leaders can get a quick pulse on the number of Distribution Centers, and their approximate locations, are necessary to meet a service goal: ensuring 95% of their demand within a 1-day drive of a DC.

In that post, we used circuity factors, a convenient rule-of-thumb that allows us to convert “as the crow flies” straight-line distance to an estimated driving distance, by adding on an additional percentage (15% is common). For example, a 300 mile straight-line distance can be estimated at 300 * 115% = 345 driving miles. You can then use that driving miles estimate, divided by a speed planning factor (in Miles Per Hour / Kilometers Per Hour), to estimate drive time.

Circuity factors are great for national-level Distribution Center planning. But they tend to be less useful at more local levels, where real-life circuity factors and speed may be quite different.

For example, compare two short trips in the same suburb of Minneapolis, Minnesota. In both trips, the origin and destination are, as the crow flies, two miles apart.

- In the first trip, both origin and destination are just off a high-speed, straight thoroughfare. The driving distance is 2.1 miles. In this case, the circuity factor will be a very low 5% ( 2.1/2 – 100% = 5%).

- In the second trip, both origin and destination are at the end of a complex set of cul-de-sacs and side streets, and are separated by a large lake. (We are talking about Minnesota, the land of cough ahem lakes.) The driving distance is 2.7 miles. In this case, the circuity factor is a very high 35% (2.7/2 – 100% = 35%).

While both trips are in the same city and the same straight-line distance, you wouldn’t use the same 15% circuity factor in your planning. It gets even more complex when you consider that shorter trips tend to have higher circuity factors than longer trips, even within the same city. Circuity factors can also be radically different between metro areas, and between urban cores, suburban areas, and rural areas.

So while circuity factors are great for national-level Distribution Center modeling, they fail at shorter distances. We need something else.

Fast and Hyperlocal Delivery

Let’s say we are an e-commerce retailer that specializes in ultra-fast delivery: we promise customers delivery within one hour of ordering, for a selected assortment of products. If we budget 30 minutes for picking and packing orders, that means our last-mile delivery stations need to be within 30 minutes’ driving distance of customers.

So how many of these last-mile delivery stations are needed in a metro area, and approximately where should they be?

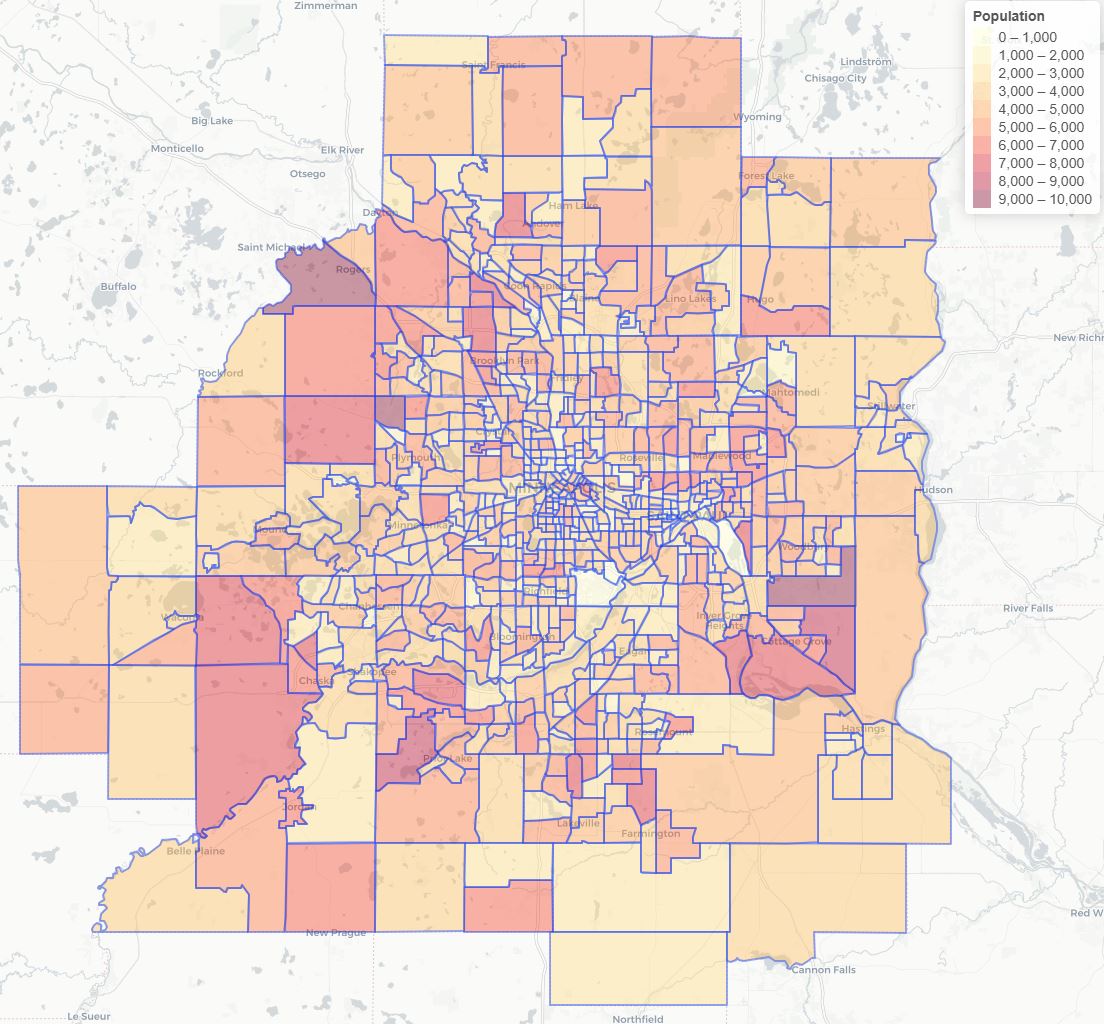

Looking at the Minneapolis-St Paul, Minnesota area, we can first look at census tracts, which are smaller than ZIP codes. In the seven-county Minneapolis-St Paul area, there are 784 census tracts; their boundaries are shown below, and are colored by population.

We will treat each census tract as a customer demand point, and assume each census tract’s demand is proportional to its population. This is usually a good starting assumption, but you should develop and use machine learning models to predict SKU-level customer demand at a hyperlocal level. This is one way that machine learning and optimization modeling are used together to make optimal supply chain decisions.

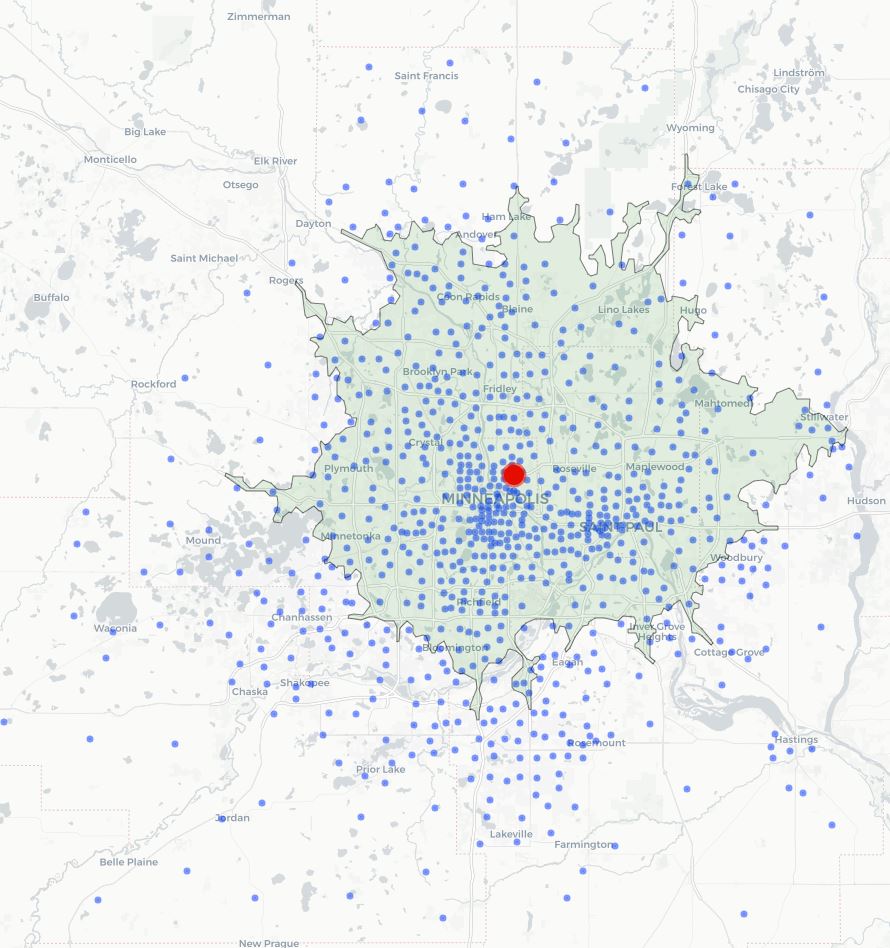

To model potential last-mile delivery station locations, we will use 153 ZIP codes across the Minneapolis-St Paul metro. We could also go more detailed, using all 754 census tracts as potential delivery station locations. Or, if we already have potential commercial real estate sites identified, we can use them instead of ZIP codes.

For each of the 153 ZIP codes, we will identify the area that can be reached within a 30-minute drive. For example, if we set up a delivery station in Northeast Minneapolis (red dot, ZIP code 55413), the 30-minute delivery zone is a light green blob in the below image. Each blue dot represents a demand point (census tract). 62% of the metro population is within a 30-minute drive of this delivery station.

We can build 30-minute delivery zones for every one of the ZIP codes we are considering for last-mile delivery stations. For each of these ZIP codes, we can then calculate which demand points are within the 30-minute delivery zone. Then, using optimization modeling, the math underlying supply chain design software, we can identify the smallest number of delivery stations, and their locations, that will enable us to cover 95% of the metro population within a 30-minute delivery zone.

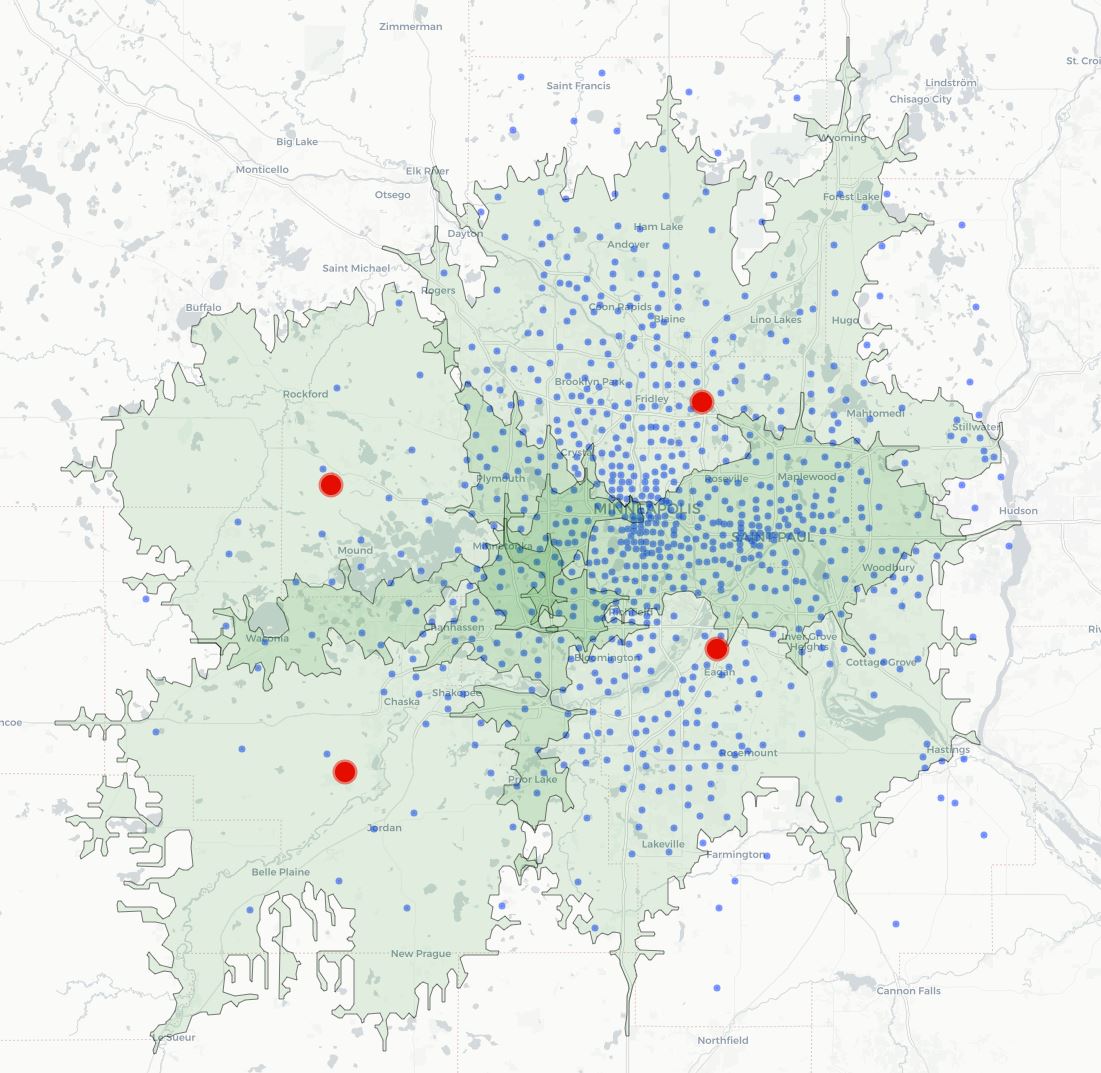

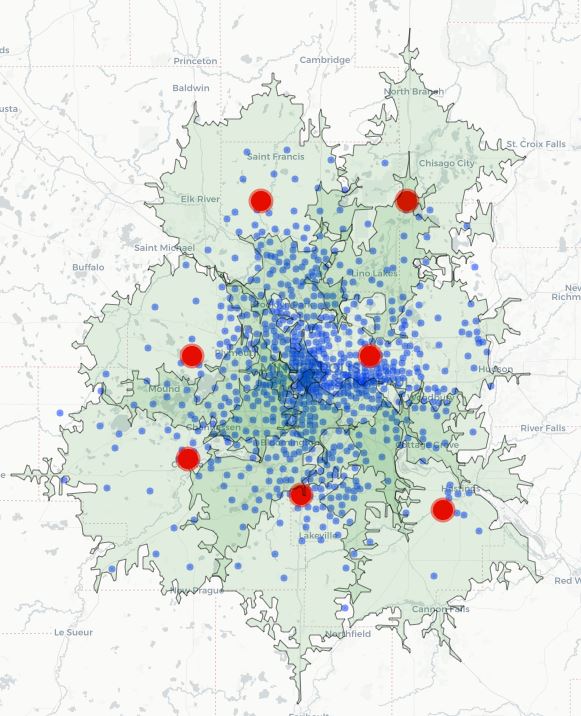

Our model suggests that you need four delivery stations to meet this 95%-within-30-minutes service goal. They are located near the suburban “corners” of the metro area. Some demand points are within the 30-minute delivery zones of multiple delivery stations. This is seen in the color differences from lightest to darkest greens. Blue dots on the white background represent the 5% of demand that is not within a 30 minute drive of any delivery station.

If we have a higher service level goal – say, 99% of the population within a 30 minute drive of a delivery station – we will need seven delivery stations.

Likewise, if our delivery promise is even faster – say, 95% of the population reachable within 15 minutes – then we will need more than four delivery stations.

Conclusion

If your business depends upon fast, hyperlocal delivery, properly locating your delivery stations is critical. Contact us to talk more about how to make smart, strategic decisions about your supply chain.

To learn more about our supply chain design consulting, read case studies or contact us.

To receive content like this and other updates from Data Driven Supply Chain, sign up here. You can unsubscribe at any time.